Compare Electric SUV Cargo Space and Maintain Hauling Capacity

Fleets are increasingly considering replacing internal-combustion engine vehicles (ICEVs) with electric vehicles (EVs). There are many factors to consider when building out a mixed-energy fleet. From comparing the total cost of ownership (TCO) between powertrains to determining the charging infrastructure needed to support EVs, fleet managers have no shortage of work to do to ensure a successful transition. Partners, such as Sawatch Labs, make this process more efficient and data-driven for fleet managers.

One consideration that might fall through the cracks is the electric SUV cargo space comparison between similar ICEVs and EVs. Some fleets are moving both people and cargo in their vehicles and may need to maximize their vehicles’ cargo capacity. If a vehicle is only used for moving people, cargo capacity is not an important factor.

Sawatch Labs recently analyzed more than 100 crossover SUVs for a client with operations throughout the U.S. The company used Subaru Foresters and Outbacks and needed EV cargo capacity to be the same or more than that of their current ICE vehicles. This requirement quickly became a constraint, as the most affordable EVs in the market offered less cargo capacity than their Subarus did.

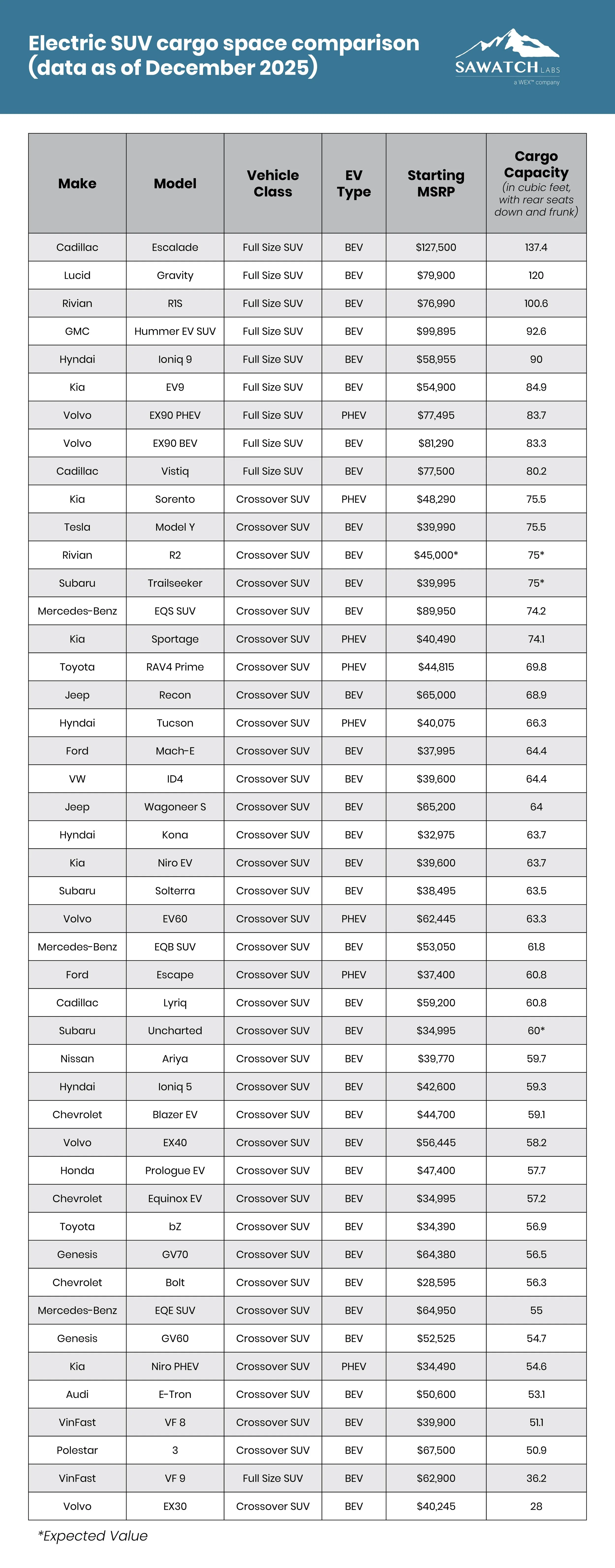

Table 1, below, provides Sawatch’s electric SUV cargo space comparison and includes a list of Crossover SUVs available in the U.S. The table illustrates cargo capacity, calculated in cubic feet. This is with the rear seats folded down and includes “frunk” space (if available). “Frunk” is the vehicle’s “front trunk”, a storage compartment offered by some EVs taking advantage of the reduced footprint of electric powertrains. This compartment is usually sealed for weatherproofing.

When reviewing Table 1, it becomes clear that there is much variability in cargo capacity among Crossover SUVs. Fleet managers need to pay special attention to these specifications if their vehicles are getting fully loaded with cargo on a regular basis.

Other Ways to Compensate for Cargo Capacity

Due to their unique designs, battery packs, and other electric components, some electric crossover SUVs offer substantially less cargo capacity than their ICE counterparts. If you are looking to go electric and are not finding Crossover SUV options that meet your cargo requirements, a few strategies you can use are discussed below.

Upsizing in Vehicle Class

An obvious solution to cargo space limitation is to move up to the next class level. A full-size SUV could be a replacement for a crossover SUV. This would allow for the cargo capacity to be maintained or expanded. However, full-size SUVs tend to be more expensive than crossovers, so the additional cargo space will come at a price.

Another option would be to upsize to an electric pickup truck. Some original equipment manufacturers (OEMs) offer electric pickup trims specific for fleets, like the 2025 Chevrolet Silverado EV Work Truck. These are more affordable but lack some of the bells and whistles found in standard ICE pickups.

Electric pickup trucks offer substantial cargo capacity in their bed, which can be enclosed either with a tonneau cover or truck cap. Tonneau covers are flat covers that seal the top of the bed, and they sometimes come as an option when buying the truck or compatible ones can be purchased afterward. Tonneau covers reduce drag by smoothing the airflow over the bed. This can improve range (especially at highway speeds). However, this increase in range can be offset by the additional weight of the tonneau cover, especially when you purchase an aluminum or fiberglass/composite one. Vinyl or fabric covers, in contrast, are very lightweight and affordable.

Truck caps, also known as toppers or canopies, are enclosed shells that sit over the entire bed, raising the roofline to provide even more covered storage. Typically, these are hard and made from materials like fiberglass or aluminum. The benefit of purchasing a fabric or canvas one is that they can be stretched over a frame. Hard caps will weigh up to 200 pounds, posing a penalty on range and total payload capacity. Canvas caps are lighter (up to 50 pounds) but not as durable. While caps offer minor aerodynamics benefits, their added weight typically offsets these gains, leading to a negligible impact on overall fuel economy and range. Studies, such as one conducted by Leer, illustrate the pros and cons of each.

Roof Cargo Solutions

If upsizing in vehicle class is undesirable, roof-mounted cargo boxes or baskets can provide additional cargo capacity. Rigid boxes typically provide up to 25 cubic feet of storage, while fabric bags offer up to 28 cubic feet. Since these roof products increase the drag of the vehicle, efficiency will be lower. According to the U.S. Department of Energy, drivers can expect up to a 25% reduction in range at highway speeds. The actual percentage depends on factors such as box aerodynamics, driving speeds, weight, and wind loads. These products can be removed when not needed, which offers flexibility, but requires additional user time for installation and removal. They also require additional storage space in the shop when not in use (fabric bags are easier to store as they can be folded).

There are two important considerations for roof-cargo solutions. First, pay attention to roof weight limitations, and load the heaviest cargo inside the vehicle. Second, check compatibility between the cargo box/basket and the roof rack system. While many SUVs come with roof rails, many have a bare or “naked” roof without any rails, tracks, or anchor points. Drilling the roof to install aftermarket rails may void warranty coverage for related components, and there are options specifically designed for bare roofs. These include towers/feet paired with vehicle-specific fit kits/clips. They can be combined with crossbars to support cargo boxes and baskets. Other options include supermagnet racks, industrial-grade racks, suction cup-based rails, or cargo bags that attach directly to the windowpanes. These options may not be as sturdy as some of the previously described racks.

Rear Hitch-Mounted Cargo Solutions

Another solution is a cargo box or tray mounted to the rear hitch of the vehicle. While enclosed boxes offer weather protection and up to 16 cubic feet of secure storage, open trays provide more flexibility for hauling bulky or oddly shaped materials. Since these devices are attached to the rear of the vehicle, the drag is significantly diminished compared to roof-mounted boxes. The actual range reduction is minimal and varies depending on driving speed, product aerodynamics, and environmental conditions.

Some EVs come with factory-installed rear hitches. Aftermarket hitches can also easily be installed by a qualified technician. When shopping for a hitch, pay attention to the hitch’s Maximum Tongue Weight (MTW) specification - the maximum vertical force a vehicle’s hitch can safely support - this will determine your maximum cargo weight. When not explicitly disclosed, Kelley Blue Book notes that the MTW can be estimated as 10% to 15% of the vehicle’s total towing capacity. Therefore, loading heavy cargo inside the vehicle and lighter cargo in the hitch box or tray will ensure optimal vehicle handling and steering stability.

Key Takeaways from the Electric SUV Cargo Space Comparison

When analyzing potential EV candidates to replace ICEVs, consider finding an electric SUV with maximum cargo space. If maintaining or extending cargo space is a priority during fleet electrification, conduct an electric SUV cargo space comparison for optimal results. If the desired EV candidates offer less cargo capacity, then upsizing to a full-size SUV or pickup truck could be a solution, although it might add considerable expense. A more affordable option could be incorporating roof or rear-hitch-mounted cargo boxes/baskets, although these come with additional considerations and tradeoffs.

Sawatch Labs, an expert in navigating these complexities, can assess if EVs will be a good economic and operational fit for your company. This expertise, combined with planning for the optimal EV charging infrastructure, positions Sawatch Labs, a WEX company, as the premier electrification analytics firm. Contact Sawatch for a free demo of its software products!